Tesla’s supply chain epitomizes efficiency and innovation, distinguishing it from traditional automotive manufacturers. Diving into its intricacies reveals the key drivers behind Tesla’s remarkable success. Here’s what makes Tesla’s supply chain stand out in terms of efficiency and innovation.

Key Takeaways on Tesla’s Supply Chain

- Tesla secures critical raw materials through strategic partnerships and vertical integration, ensuring supply chain stability and cost efficiency.

- The company prioritizes sustainability by focusing on ethical sourcing, recycling, and reducing its environmental impact.

- Advanced manufacturing processes, including Gigafactories and modular design, enable high efficiency and flexibility.

- Tesla’s direct-to-consumer sales model enhances profitability and customer satisfaction by maintaining control over pricing and experience.

- Technology integration, such as data analytics, AI, and IoT, drives Tesla’s supply chain efficiency and responsiveness.

Tesla [TSLA] has revolutionized not just its products but also the methodologies that propel these products to market. Their supply chain is a fundamental component of their overarching strategy, emphasizing both efficiency and sustainability. Tesla’s unique approach integrates advanced technologies, strategic partnerships, and a deep commitment to environmental sustainability.

Interested in data on top US companies?

Save tens of hours in 2 minutes with some of our best-selling Excel files:

The Components of Tesla’s Supply Chain

To fully appreciate Tesla’s supply chain, it is crucial to dissect it into its primary components: sourcing materials, manufacturing processes, distribution, and technology integration.

Sourcing Materials

The procurement of essential materials is pivotal for Tesla, especially regarding components such as batteries and electric motor systems. Tesla’s sustainability and innovation focus is evident in its sourcing strategies.

- Strategic Partnerships: Tesla engages in strategic partnerships with mining and chemical companies to secure necessary raw materials like lithium, cobalt, and nickel. This guarantees control over supply chains and cost stability, essential in a competitive landscape. For example, Tesla has partnered with suppliers to ensure that each part meets strict quality standards while maintaining cost efficiency.

- Sustainability: The company aligns its sourcing methods with its mission to promote sustainability, resonating with eco-conscious consumers and strengthening brand loyalty. Tesla has significantly improved its supply chain sustainability by focusing on ethical sourcing practices, which is highlighted by its jump to third place in the Automakers Supply Chain Leaderboard.

- Vertical Integration: By incorporating suppliers directly into their operations, Tesla diminishes reliance on third-party vendors. This approach bolsters quality control and reduces costs, allowing the company to remain agile in its supply chain management. Tesla’s vertical integration strategy has also enabled it to maintain tighter control over its raw materials and reduce exposure to market fluctuations.

- Recycling Initiatives: Tesla’s commitment to sustainability extends to recycling old batteries, providing a secondary source of raw materials while minimizing waste and illustrating a circular economy model. The company’s closed-loop system for battery recycling is part of its broader environmental strategy, as discussed in a comprehensive analysis.

Manufacturing Processes

Tesla’s manufacturing processes embody a potent blend of cutting-edge technology and innovative practices.

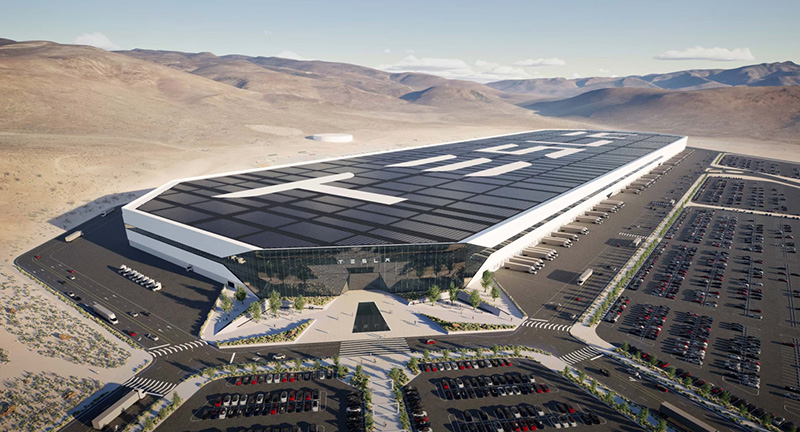

- Gigafactories: Central to Tesla’s operations, Gigafactories maximize production efficiency while dramatically reducing logistics costs. These expansive facilities allow for better integration across the supply chain and play a crucial role in scaling production. Tesla’s Gigafactory approach was instrumental in overcoming early production challenges, as noted in this analysis.

- Automation and Robotics: Extensive automation in production lines enhances operational efficiency and mitigates human error. However, Tesla learned from its early over-reliance on automation during the Model 3 production, leading to a more balanced approach that combines automation with human labor, a lesson highlighted in industry reviews.

- Lean Manufacturing: Employing lean principles, Tesla streamlines operations, minimizes waste, and effectively allocates resources, keeping costs down and quality high. This method allows faster response times to changes in demand.

- Modular Design: Tesla’s focus on modular design enables flexibility in manufacturing and quick adjustments to changes in consumer demand or component supply, illustrating a forward-thinking approach to production.

Distribution Strategies

Tesla’s distribution strategies break from conventional automotive practices and offer valuable lessons for other industries.

- Direct Sales Model: By opting for a direct-to-consumer sales approach, Tesla maintains control over pricing and customer experience, enhancing both profitability and loyalty. The company’s direct sales model is a significant departure from traditional automotive sales channels, a key element of Tesla’s strategic vision.

- Online Sales: Tesla’s robust online sales platform streamlines the purchasing process, allowing customers to configure, order, and track their vehicles conveniently. The self-service built in Tesla’s business model inspires other companies to develop their e-commerce capabilities.

- Delivery Coordination: Efficient logistics and delivery coordination ensure vehicles reach customers promptly and in excellent condition, improving overall customer satisfaction. This includes using data analytics for tracking and adjusting delivery times, a strategy that is studied extensively.

- Showroom Experience: By offering an immersive experience in showrooms that focuses on education and interaction rather than hard-selling, Tesla increases engagement and brand affinity, providing a template for creating customer-focused environments.

The Role of Technology in Tesla’s Supply Chain

Technology serves as a cornerstone of Tesla’s supply chain efficiency and innovation, enabling responsive operations and strategic insights.

- Data Analytics: Tesla leverages advanced big data analytics across its supply chain to forecast demand, manage inventory, and optimize efficiency. Companies can utilize similar analytics tools to analyze trends and reduce risks, streamlining their operations.

- Blockchain Technology: To bolster transparency in sourcing and production, Tesla explores blockchain technology that enhances traceability and builds consumer trust, addressing growing concerns about ethical sourcing.

- Artificial Intelligence: Utilizing AI in inventory management and demand forecasting markedly improves operational flow and decision-making efficiency. Companies integrating AI can enhance adaptability, reducing operational bottlenecks.

- Internet of Things (IoT): IoT devices facilitate real-time tracking of assets and enhance supply chain visibility, allowing for proactive management responses to disruptions, which is critical in today’s fast-paced environment.

- Supply Chain Automation: Tesla employs automation not just in manufacturing but also in logistics and inventory management, pushing further advancements like autonomous deliveries, which could redefine supply chain efficiency.

Sustainability Initiatives

Tesla’s commitment to sustainability is evident across its supply chain. The company has significantly reduced its environmental footprint through various initiatives, such as using renewable energy in its operations and sourcing materials responsibly. Tesla’s recent improvements in supply chain transparency, particularly regarding Scope 3 emissions, have been recognized in industry rankings, as highlighted by Teslarati’s study.

Challenges and Solutions

While Tesla’s supply chain garners admiration for its efficacy, there are challenges that require strategic responses.

- Global Supply Chain Risks: Disruptions such as pandemics or geopolitical tensions can impact supply chain stability. Companies should diversify their suppliers and build resilience through robust risk management strategies, including scenario planning.

- Regulatory Changes: As environmental regulations evolve, Tesla must adapt rapidly. Staying informed about industry standards and fostering proactive compliance efforts can help mitigate disruptions.

- Cost Volatility: Fluctuating raw material prices can jeopardize profitability. Businesses may benefit from developing financial forecasting models to anticipate costs and strategize accordingly, incorporating hedging techniques when feasible.

- Talent Acquisition and Retention: As technology evolves, attracting and retaining skilled talent is crucial. Companies should invest in continuous training initiatives and build a strong employer brand to appeal to tech-savvy individuals.

- Supply Chain Disruptions: A failure in one part of the chain can cascade downwards. Companies can invest in flexible supply chain designs and technology that offer visibility to quickly adjust when disruptions occur.

Exploring Tesla’s supply chain reveals invaluable insights into efficiency and innovation, encouraging other businesses to rethink their operational frameworks. By adopting relevant strategies from Tesla’s approach, companies can enhance their effectiveness and sustainability across all facets of their supply chain. Embracing these principles can lead to a transformational impact, ensuring long-term success and resilience in a rapidly evolving business landscape.

![Top 1200 UK Companies [FTSE All-Share + FTSE AIM All-Share] – Excel Download](http://store.disfold.com/wp-content/uploads/sites/11/2024/05/top-1200-uk-companies-ftseallshare-aimallshare-small.jpg)

![Top 500 Australian Companies [All Ordinaries] – Excel Download](http://store.disfold.com/wp-content/uploads/sites/11/2021/04/top-500-australian-companies-allordinaries-small.jpg)