In today’s fast-paced technology landscape, Apple’s supply chain serves as a benchmark for efficiency and innovation, offering valuable lessons for businesses seeking to optimize their operations and stay competitive. Understanding this sophisticated model provides critical insights into how Apple maintains its leadership in the tech industry.

Key Takeaways on Apple’s Supply Chain

- Vertical Integration: Apple controls key aspects of its supply chain, ensuring high product quality and rapid adaptability to market changes.

- Global Sourcing: Apple diversifies its suppliers across regions, reducing risks and securing premium components at competitive prices.

- Efficiency: Through Just-In-Time inventory management and automation, Apple minimizes costs while maintaining high agility and responsiveness.

- Innovation Partnerships: Apple collaborates closely with suppliers to drive innovation, accelerating the development of new technologies.

- Sustainability Focus: Apple is committed to carbon neutrality and ethical sourcing, positioning itself as a leader in sustainable supply chains.

- Challenges: Apple faces risks from geopolitical tensions, supply disruptions, and the rapid pace of technological advancements.

Understanding Apple’s Supply Chain Model

At the heart of the success of Apple [AAPL] is its meticulously crafted supply chain model, which balances control, flexibility, and collaboration. By blending vertical integration, global sourcing, and collaborative partnerships, supply chain management, one of the strategic and tactical pillar of Apple’s success, ensures the firm’s product quality while maintaining resilience against disruptions.

- Vertical Integration: Apple exerts significant control over key parts of its supply chain, managing everything from manufacturing and product design to retail. This enables rigorous quality control and reduces reliance on external suppliers. By owning critical aspects of the production process, Apple can quickly adapt to market changes and swiftly introduce innovations.

- Global Sourcing: Apple sources materials and components from suppliers worldwide. This approach allows Apple to secure access to the best components at competitive prices while minimizing exposure to supply chain risks. By diversifying suppliers across various countries, Apple also hedges against potential geopolitical or natural disruptions.

- Collaborative Partnerships: Apple fosters close relationships with key suppliers to co-develop innovative technologies and reduce time-to-market for new products. For example, Apple’s collaborations with semiconductor companies like TSMC enable the integration of cutting-edge chips into devices like the iPhone and Mac. These partnerships allow Apple to maintain a technological edge while ensuring rapid scalability.

By understanding Apple’s supply chain model, other businesses can learn how to enhance quality, drive innovation, and achieve operational flexibility.

Efficiency in Apple’s Supply Chain

Apple’s supply chain is renowned for its efficiency. From inventory management to advanced technology integration, Apple employs several strategies to reduce costs, enhance agility, and boost overall productivity.

Just-In-Time Inventory Management

A key pillar of Apple’s supply chain efficiency is its use of Just-In-Time (JIT) inventory management, which reduces excess stock and minimizes storage costs.

- Reduced Holding Costs: JIT ensures that materials and components are delivered precisely when needed, minimizing warehousing costs and reducing the risk of obsolete inventory. This approach enhances cash flow and operational efficiency, allowing Apple to allocate resources more effectively to innovation and expansion.

- Operational Agility: In the rapidly evolving tech industry, Apple’s JIT system provides the agility needed to respond to market shifts and product demand changes. This flexibility is crucial when launching new devices, ensuring that Apple can meet customer demand without being burdened by overstocked components.

- Cash Flow Optimization: Lowering inventory levels frees up capital that can be reinvested in R&D and marketing, helping Apple maintain its competitive edge in a fast-moving industry.

Adopting JIT inventory management allows businesses to reduce waste, improve cash flow, and respond faster to market changes.

Advanced Technology Integration

Apple leverages advanced technologies to optimize its supply chain, including automation and data analytics.

- Automation: Apple uses robotics and automated manufacturing systems to increase production speed and maintain high product quality. Automation reduces human error and improves efficiency, particularly in the assembly of devices like iPhones and Macs.

- Data Analytics: By using sophisticated data analytics, Apple can forecast demand more accurately, optimize logistics, and minimize delays. Real-time data allows Apple to manage its global supply chain more effectively and make informed decisions.

- Predictive Maintenance: Apple applies predictive analytics to maintain production equipment, identifying potential issues before they cause significant disruptions. This foresight allows for continuous production, minimizing downtime and ensuring products reach the market on time.

Integrating technologies like automation and data analytics can help businesses improve operational efficiency, minimize downtime, and enhance product quality.

Innovation in Apple’s Supply Chain

Innovation is deeply embedded in Apple’s supply chain, ensuring that the company remains at the forefront of technology development and sustainability, and one step ahead of its competitors.

Supplier Innovation Programs

Apple nurtures supplier relationships to foster innovation throughout its supply chain.

- Investment in Suppliers: Apple financially supports its suppliers, encouraging them to enhance their technological capabilities, notably in Europe and Vietnam. These investments benefit both parties, leading to the creation of new technologies and enabling faster product development.

- Collaborative Design: Apple works closely with suppliers during the product design phase to ensure that new technologies are seamlessly integrated into its devices. It also shares design with external developers to facilitate external apps integration. This collaboration speeds up the development process and allows Apple to introduce groundbreaking innovations more quickly.

- Knowledge Sharing: Apple regularly conducts workshops and training sessions for suppliers, promoting knowledge exchange and keeping all partners up to date with industry advancements. This practice ensures that suppliers are well-equipped to meet Apple’s high standards.

By forming strong partnerships with suppliers, businesses can accelerate innovation and drive mutual success.

Sustainability Initiatives

As consumer demand for environmentally responsible companies grows, Apple has made supply chain a key part of its sustainability and innovation efforts, emerging as a leader in sustainable supply chain practices.

- Environmental Responsibility: Apple is committed to achieving carbon neutrality across its entire supply chain by 2030. This involves switching to renewable energy sources in its production facilities and reducing carbon emissions from its suppliers.

- Ethical Sourcing: Apple implements strict guidelines to ensure responsible sourcing of raw materials, particularly concerning conflict minerals like cobalt and lithium. These practices enhance the company’s reputation and build consumer trust.

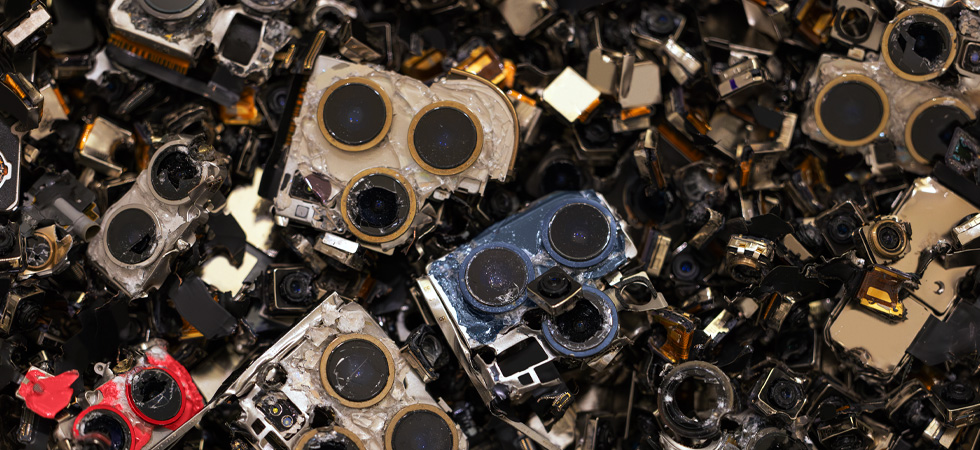

- Recycling and Circular Economy: Apple’s recycling programs, such as Daisy, its disassembly robot, help recover valuable materials from old devices, contributing to a circular economy. This approach reduces waste and promotes sustainability, while also encouraging customers to return old products for recycling.

Adopting sustainability practices not only enhances a company’s brand image but also appeals to eco-conscious consumers, helping drive long-term success.

Challenges in Apple’s Supply Chain

Despite its successes, Apple’s supply chain faces significant challenges, ranging from geopolitical risks to supply disruptions and rapid technological advancements.

- Geopolitical Risks: Trade policies and tariffs, particularly between the U.S. and China, pose ongoing challenges for Apple’s supply chain. Geopolitical tensions can lead to increased costs and interruptions in the flow of goods and components.

- Supply Disruptions: Natural disasters, pandemics, or regional instability can disrupt the flow of key components like semiconductors, which are critical for Apple’s devices. Apple mitigates these risks by diversifying its supply base and maintaining strategic inventory.

- Technological Disruptions: Rapid advances in technology often necessitate quick changes in Apple’s supply chain to stay competitive. Apple must continually adapt its processes to incorporate the latest innovations while maintaining its efficiency and quality.

Understanding these challenges can help other businesses develop robust contingency plans and diversify supply chains to improve resilience in an unpredictable global environment.

By leveraging strategies like JIT inventory management, investing in advanced technologies, fostering innovation through supplier partnerships, and prioritizing sustainability, companies can significantly enhance their operational efficiency and adaptability. Learning from Apple’s supply chain success provides a roadmap for businesses looking to build a more resilient and innovative supply chain.

![Top 1200 UK Companies [FTSE All-Share + FTSE AIM All-Share] – Excel Download](http://store.disfold.com/wp-content/uploads/sites/11/2024/05/top-1200-uk-companies-ftseallshare-aimallshare-small.jpg)

![Top 500 Australian Companies [All Ordinaries] – Excel Download](http://store.disfold.com/wp-content/uploads/sites/11/2021/04/top-500-australian-companies-allordinaries-small.jpg)